- Combined 44+ years of Thermoplastic extrusion design/processing experience implementing prototype to production solutions.

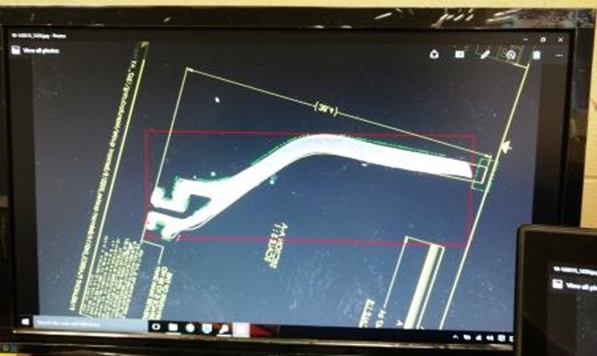

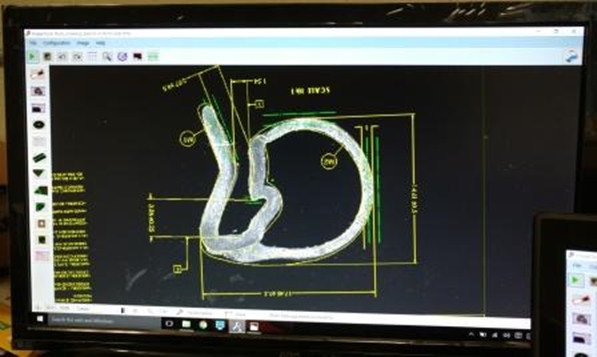

- Extrusion tooling design & building.

- Specialized, innovative extrusion and Secondary finishing design/practices aimed at economic costs: tooling, process and components.

- Superior understanding of Thermoplastic Materials.

8211 Graphic Dr. NE, Belmont, MI 49306

8211 Graphic Dr. NE, Belmont, MI 49306

Call (616) 262-4991

to get a quote on your Custom Plastic Profile Extrusion Project

Product Realization Stages

Customer Interface

- Concept Development

- Material Design & Development

- Engineering Estimates

- Prototypes

- Product Design Assistance

- Quotation

- Process Development

- Program Management

Realization Techniques

- Advanced product quality planning

- Production part approval process

- Value Analysis/Value Engineering

- Kaizen

- Cost Improvement

- Quality Improvement

Premiere custom extruder!

We specialize in providing high quality, precisely engineered, customer-specific plastic extrusion products. We serve small, medium and large-sized OEMs in a wide variety of industries.

We specialize in providing high quality, precisely engineered, customer-specific plastic extrusion products. We serve small, medium and large-sized OEMs in a wide variety of industries.

Our extrusion lines are monitored with state of the art systems that allow us to better control our processes ensuring stability while monitoring in real-time the shape and surface quality of the extrusion. Our processing equipment performs finishing operations as automated in-line processes, taking the product straight from the extrusion line to packaging for excellent product lead times in our highly efficient production process.

Secondary Capabilities

- Cut to length

- Assembly

- In-line Taping

- Injection Molding onto thermoplastic extrusions

- Punching

- Notching

- Heat Forming

- Welding

- Ability to tool to meet the project needs